ERP software solution for variant manufacturing

unitop – the end-to-end solution for your industry.

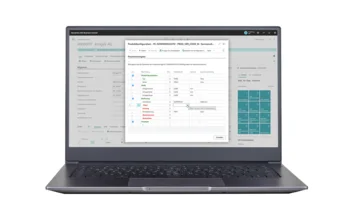

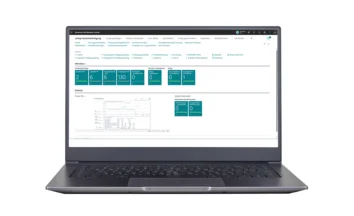

Are you a variant manufacturer and are you looking for a solution that provides end-to-end support for your variants, from sales and marketing to production? With unitop, you can produce compliant and reliably costed quotations and transparently guide them through the planning and production stages. Our business solution is based on Microsoft Dynamics 365 Business Central and combines sales and marketing, configuration, production, logistics and finances on a single platform. Manage your configuration documents, drawings and successive revisions in an audit-proof way in the integrated DMS: variants are clearly traceable at any time. From commissioning to production feedback, your scanners, label printers and devices on the internal network can be securely connected via the unitop HUB. In the role centre, your sales and marketing and customer service departments can control enquiries, quotation and configurations statuses, deliveries and complaints.

Developed using sector-specific competence & Microsoft expertise

unitop – our end-to-end ERP solution for the variant manufacturing sector

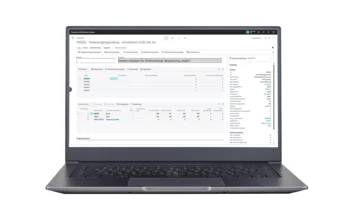

We have a detailed knowledge of requirements in variant manufacturing: options, dependencies, prices and deadlines need to be reconciled in a coordinated way. Based on many years of project experience and our in-depth expertise in the sector, we have developed a solution that combines rules-based derivation, reliable calculation and end-to-end production data within a single system. Whether in variant manufacturing (CTO) or in modular-based ATO scenarios with pre-fabricated modules, unitop can quickly transform a customer’s requirements into a technically consistent, costed order.

As a Microsoft Solutions Partner for business applications, we champion technological ingenuity, scalability and long-term security of investment. With unitop, you benefit from a solution that seamlessly integrates configuration, planning, production, quality and logistics – on a future-proof Microsoft platform.

Sector-specific functions in unitop

Our ERP solution for the variant manufacturing sector – its main functions at a glance

DMS, EDI & MDC

Additional key functionalities for your variant manufacturing processes

Alongside the core, sector-specific functions, unitop also provides some powerful, additional functionalities to make your processes even more transparent and efficient:

In the integrated DMS, you can store any documents or files, such as specifications, drawings, successive revisions, test protocols, certificates, and order and delivery documents. All documents are linked to the relevant data, such as the order number, item number or series number – in a secure and audit-proof way.

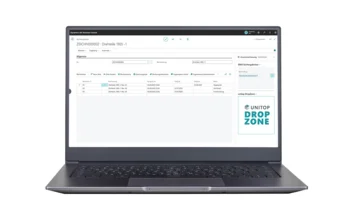

If needed, documents such as enquiries, quotations, order confirmations, despatch advices, invoices, and relevant master data and information about revisions are automatically shared with customers, suppliers or contract manufacturers, shortening processing times, reducing errors and creating transparency in procurement and logistics.

Movements of goods, transfers and production feedback can be captured directly in the production hall and the warehouse – by mobile app or scanner. Your stocks, orders, and series and batch transfers are kept up to date and traceability is guaranteed at all times.

Testimonials

Innovating. Transforming. Succeeding.

We provide comprehensive support — from process analysis and the appropriate unitop licensing to implementation and ongoing operation on the Microsoft platform.